Conductive Compounds, Masterbatches, & Static Dissipative Alloys

MDI offers electrically and thermally conductive compounds, concentrates, and static dissipative alloys utilizing a range of conductive carbon blacks, fillers, and additives. MDI also offers conductive products using advanced materials such as graphene, graphite, and carbon nanotubes that provide next generation specialized performance.

Most commercially available polymers are excellent insulators by virtue of their inherently high resistivity, low dielectric constant, and negligible power factor – all virtually independent of changes in temperature, humidity, and frequency. But these properties make polymers susceptible to very high electrostatic charge build-up. The propensity of polymers to build-up static electricity coupled with the slow static dissipation rate leads to significant problems like:

- Contamination due to attraction of dirt

- Blocking of plastic films and adhesion of fibers

- Agglomeration of powders in conveying and packaging systems

- Explosive hazards in mines, hospital operating theaters, and other areas where solvent/explosive vapors could build up

- Damages to electronic components during manufacture, storage, and transportation due to electrostatic discharge

With electrical components becoming the norm in nearly all consumer, commercial, and industrial products, product developers from a wide array of industries are now seeking semi-conductive thermoplastics that allow a controlled dissipation of electrostatic charges.

Carbon Black Filled

MDI’s experience with carbon black processing translates very well to conductive applications. MDI offers conductive compounds and masterbatches utilizing a variety of conductive carbon blacks and other additives. Carbon black selection is critical when designing a conductive thermoplastic compound. Depending on which polymer base and end use properties are required, certain types of carbon black may or may not be suitable for consideration.

Conductive carbon blacks can be used as fillers to transform insulating plastics into permanently semiconducting materials. These conductive compounds offer the best price/performance ratio.

Optimal balance between conductivity, physical properties, and processability can be achieved using 5%–50% of carbon black depending on the resin system and the grade of carbon black. Additional benefits include resistance to UV radiation and oxidative degradation.

The conductive grades of carbon black are all characterized by small primary particle size, large surface area, high structure (interparticle agglomeration and branching), and a surface with low oxygen containing groups.

Typically, for a specific polymer system, the conductivity increases with

- Decreasing particle size

- Increasing surface area

- Increasing structure

- Decrease in the number of oxygen containing surface groups like -CO, -COOH, etc. of the carbon black.

The properties of the polymer system that affect the conductivity of a polymer-carbon black system are:

- The interfacial adhesion between the polymer and carbon black

- The crystallinity and crystallization characteristics of the polymer

- The morphology in case of alloys and co-polymers

- The inherent resistivity of the polymer

Moreover, the processing method, rheology, and the extent of carbon black dispersion in the polymer affect the conductivity of these compounds. These classes of compounds are widely used in:

- Packaging for static sensitive electronic and explosive devices

- Antistatic flooring and sheeting for hospitals, semiconductor industry, and mines

- Antistatic belting, hoses, and molded components for automotive, mining and electronics industry

- Power and telecommunications cable sheathing and shielding applications

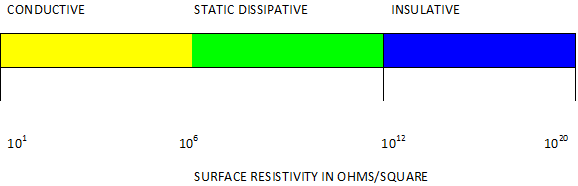

MDI offers both Conductive and Static Dissipative Compounds

Graphite and Graphene Filled

Graphite and graphene powders impart both electrical and thermal conductivity when compounded into polymers. Although the percolation threshold is higher with graphite fillers, graphite has the capability of being loaded at higher weight percentages than carbon black and imparts very low resistivity, in some cases as low as 10e2 ohm-cm. Graphene performs better at lower loadings compared to graphite in electrical and thermal applications. For thermally conductive applications, compounds can exhibit heat transfer values in the 5 - 20 w/mk range. Applications for graphite and graphene filled compounds include: fuel cell bipolar plates, heat sinks and housings, and geothermal pipes.

Real-Stat Static Dissipative Alloys

MDI produces a line of static dissipative polymer alloys where the static dissipative properties are permanent. Typical surface resistivity for articles produced from Real-Stat alloys range in the 10e9 - 10e11 ohms/sq. Real-Stat alloys do not contain high loadings of fillers and can usually be processed similarly to natural resins. The appearance of Real-Stat alloys can range from almost clear to an off white or slight yellow tint. Being close in color to natural resins, Real-Stat alloys can be easily colored using standard or custom color masterbatches. Real-Stat alloys are offered in polymer systems such as LLDPE, HDPE, PP, HIPS, TPO, and certain nylons. Applications for Real-Stat alloys are: ESD films and sheets, molded bins, and ESD packaging.

Carbon Nanotubes (CNTs)

Carbon Nanotubes, both multi-walled and single walled, are at the cutting edge of material science. Unlike many traditional carbon based fillers, CNTs are very hard to disperse due to their anisotropic structure. A well dispersed CNT nanocomposite achieves superior electrical and mechanical properties at lower loadings compared to traditional carbon based fillers. CNTs are being evaluated for breakthrough applications in energy storage, thermal and electrical conductivity, structural reinforcement, and many other areas. MDI is excited to lead the charge into the future with both single-wall (SWCNTs) and multi-wall carbon nanotubes (MWCNTs) new product development.

For more information on conductivity in plastics, please see Insights on Conductive Plastics.

All Rights Reserved 2017

https://caa.ebms.com/Modern%20Dispersions,%20Inc./index.html