Black Masterbatch and Concentrate

With 50 years of carbon black compounding experience, we *are* the black masterbatch specialists. MDI produces a wide variety of black masterbatches, concentrates, and compounds that provide superior UV protection, FDA compliance, high-jetness, blue-tone, high loadings, low-tint performance, and customizability.

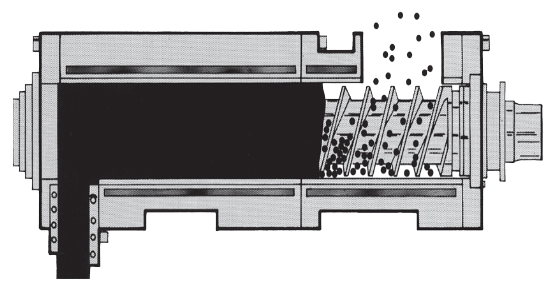

Black masterbatches are high concentrations of carbon black, typically 15 - 50% dispersed in thermoplastic resins which act as a carrier or binder. Other black pigments, such as nigrosine dye and bone black can also be used depending on the application and resin system. Masterbatches and concentrates allow plastic processors to utilize carbon black and other dry powders in a pre-dispersed pellet form, allowing easy incorporation in extrusion and molding processes. These masterbatches are then incorporated into various polymers to impart properties such as color, UV resistance, and electrical or thermal conductivity.

Black Masterbatch can be produced in almost any thermoplastic resin; however the most common resins tend to be polyolefins, styrenics, and engineering resins such as polycarbonate and nylon. Typical markets which require large quantities of Black Masterbatch are:

- Blown Film

- Extrusion Coating

- Pipe

- MDI's black masterbatch grade PE-535-42 is approved in PE-3408 and PE-4710 HDPE pressure pipes

- Agricultural (geomembrane and drip tape)

- Fiber and Multi-Filaments

- Automotive Compounds

- Wire and Cable

- FDA / Food Packaging

- MDI has extensive experience with the FDA and Health Canada stewardship process.

With decades of experience, MDI has a strong background in all aspects of black masterbatch and concentrate production. Our black masterbatches and concentrates are designed to meet stringent quality standards to deliver the functionality that our customers require. Products include blacks that are highly dispersed, provide UV protection, flame retardancy, regulatory compliance, and either high or low tinting strength. MDI also provides a line of conductive masterbatches and compounds for electrical and thermal conductivity applications.

One of MDI's recent innovations is EcoBlack, a line of black masterbatch containing carbon black made from recycled post-consumer tires. Every ton of feedstock used in the recovery process prevents one ton of oil being consumed and 1.4 tons of CO2 emission. EcoBlack can be used in any application traditional black can, while being environmentally friendly and economical.

See MDI's technical library, Fundamentals of Carbon Black and Insights on Dispersion for more information on the basics and science behind carbon black processing.

All Rights Reserved 2017

https://caa.ebms.com/Modern%20Dispersions,%20Inc./index.html